A 2008 Peugeot 308 with a 1.4l 16v engine, code 8FS, had a dashboard warning light indicating that the vehicle was overheating even when the engine was cold.

The cooling fan was continuously running and ultimately causing battery drain, while an anti-pollution message had been on the information screen for some time.

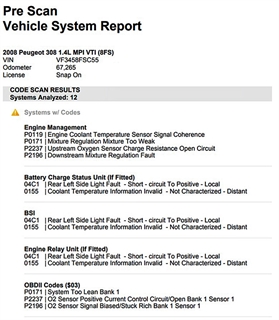

Running a pre-scan report with a Snap-on diagnostic tool highlighted several fault codes, indicating that the two warnings were separate issues.

|

| The pre-scan vehicle system report for this Peugeot 208 case study. |

This case study concentrates on the P0119 code in the ECU, which is linked to the 0155 code in BSI.

Other codes, relating to the O2 sensor and system too lean, were present.

Clicking Diagnose on the P0119 code opened up the Intelligent Diagnostics page on the scan tool and a look at the Verified Top Repairs section showed there are common repairs for this code to indicate a coolant temperature repair sensor issue.

The Technical Service Bulletins (TSB) tab highlighted the availability of a manufacturer bulletin for this vehicle and trouble code.

A further check of the verified repairs in SureTrack found several examples of this fault occurring, indicating that it was a common concern and that it was most likely to be down to a faulty coolant temperature sensor.

This was backed up by the related real fixes within SureTrack. The thermostat housing on this vehicle can also be replaced as it comes with a new sensor, which would fix the issue.

The manufacturer-released TSB for this problem showed that a modified sensor was available, and it also supplied the necessary part number.

|

|

|

| |

Click on these images for examples of the TSB in this case study. |

|

Live data within Intelligent Diagnostics showed a high temperature reading but as the engine was cold, this indicated that either the wiring or sensor had shorted.

With all of the above in mind, it was still important to take some voltage readings at the sensor in case of a wiring issue.

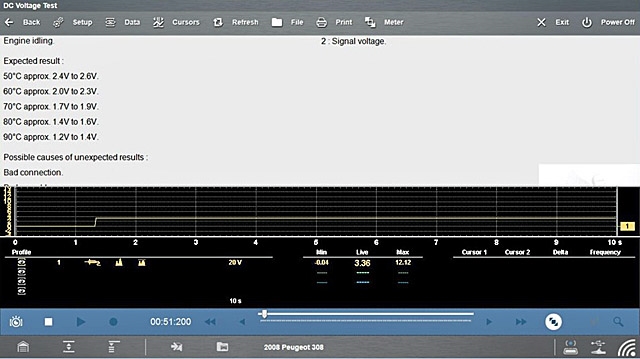

Intelligent Diagnostics pre-selected the relevant component test, also showing some expected known good readings and where to probe to obtain a voltage reading.

With the sensor signal wire back-probed initially, the sensor output was 0.01V. This indicated either a shorted sensor or a short in the wiring.

Unplugging the sensor showed a reading of 3.36V on the signal wire, indicating that the wiring was not shorted.

On most occasions, the sensor should have a 5V bias but on this Peugeot a 3.36V bias is correct.

|

| A component test showing live data on this case study. |

The instructions on the TSB were followed and the thermostat housing was replaced with a modified wiring harness. It had shown signs of leaking, otherwise just the sensor would have been replaced.

A subsequent test showed that the engine reported a correct reading when cold.

After fitting the new thermostat housing and vacuum filling the cooling system, with the engine started from cold, the temperature gauge indicated a cold engine and the fan did not run at this point.

Running the engine up to temperature to ensure the cooling system operates correctly, the fan cut in as expected.

The temperature did not rise to excessive temperature and no codes returned for the coolant temperature sensor.

Date posted: 7 September 2020