The Snap-on EH&S Management System serves as the organizing framework that enables us to achieve and sustain our environmental, operational, and business objectives. Environmental risks and liabilities—most directly related to potential changes in regulations—are managed through the Snap-on EH&S Management System, which is applied worldwide. The System is based upon continual improvement and is certified to ISO 14001:2015 and OHSAS 18001:2007, verified through Det Norske Veritas (DNV) Certification, Inc.

Our EH&S Management System allows for proactive management of regulatory requirements and deadlines and completion of corrective actions. Reviewing our performance against the stated goals and principles ensures the ongoing value of the System.

Internal environmental compliance reviews are conducted regularly at all Snap-on facilities to verify that we are meeting applicable government requirements, as well as internal standards. Our internal self-assessments and environmental reviews go well beyond simple compliance with regulatory requirements, resulting in ever-increasing levels of performance. We hold regular meetings with facilities to close identified gaps and promote continual learning throughout the process.

EHS Policy Statement & ISO CertificatesEnvironment Policy

Our facilities conserve energy and natural resources through the prudent use of energy, the elimination or reduction of pollution at its source, and the proper disposal or effective treatment of any waste that is not recycled.

Highlights of these efforts include the following:

ENERGY: Snap-on is continually searching for areas of improvement and new innovations to maximize the output of our energy usage. In turn, we remain committed to making capital investments to increase the operational efficiency of our manufacturing facilities.

AIR: All Snap-on locations with emissions are properly permitted and comply with applicable air-related emission requirements. To protect air quality in the communities in which we have facilities, Snap-on has removed equipment, replaced processes, and invested in equipment to maximize efficiencies that ensure compliance.

WATER: Snap-on has designed, developed, and patented technology to reduce the water requirements in our manufacturing operations. The treated water at our manufacturing locations that is returned to its source meets or exceeds the applicable regulatory standards.

USED OIL: Used oil is recycled per local, state, country, or regional requirements. Our facilities have established agreements with contractors to dispose of or recycle any used oil appropriately.

WASTE: The disposal of industrial waste complies with all local, state and government requirements.

RECYCLED WASTE: Throughout our operations we strive to create processes that maximize raw material yield and minimize recycled and industrial waste. Any broken tools or end-of-life products can be returned to Snap-on for appropriate processing and recycling.

In 2008, Snap-on began voluntarily quantifying and reporting greenhouse gas (GHG) emissions to the Carbon Disclosure Project (CDP) on an annual basis. Our participation in the CDP allows Snap-on to better integrate climate risks and opportunities into our business practices and inform investors of our environmental performance.

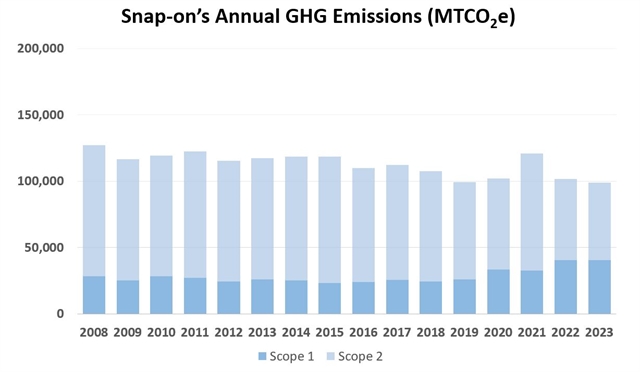

Snap-on’s GHG Emissions

As shown on figure 1 below, Snap-on’s overall annual GHG emissions have remained fairly consistent from year to year—despite growing operations—as a result of our company’s commitment to improve efficiency in our manufacturing operations and conventional energy usage.

Figure 1

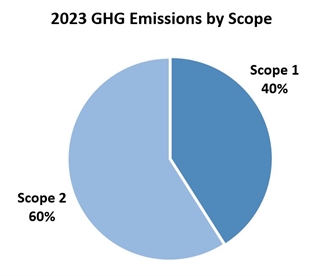

Of note, the vast majority (approximately 60%) of Snap-on’s GHG emissions are classified as Scope 2 emissions* as shown on figure 2 below, which come from electricity purchases/acquisitions, compared to Scope 1 emissions, which are emitted directly from sources over which Snap-on has control.

Figure 2

*Scope 2 emission factors for historical data were updated for 2010, 2016, and 2019

GHG Equivalencies: Making Sense of the Numbers

From a comparative perspective, Snap-on’s 2020 calendar year emissions are equivalent to the following, according to EPA’s Greenhouse Gas Equivalencies Calculator:

- 22,213 typical passenger vehicles on the road each year, or 0.008% of the 256.6 million registered cars in the U.S. in 2020.

- 11,492,855 gallons of gasoline consumed, or 0.008% of the 142.98 billion gallons of gasoline consumed per year in the entire U.S. in 2017.

- 18,552 homes’ electricity use (0.013%) and 12,300 homes’ energy use (0.008%) for one year compared to approximately 140.8 million total housing units in the U.S. in 2020.

- 236,469 barrels of oil consumed in an entire year compared to approximately the 20.47 million barrels of oil consumed daily in the U.S. in 2019.

- 0.026 coal-fired power plants in one year.

Commitment for the Future

Snap-on has and continues to provide solutions to reduce the company’s environmental impact by identifying areas for improvement, continually seeking alternatives to improve efficiency in our own conventional energy usage, and implementing new innovations to reduce our impacts on the environment.

We remain committed to making capital investments to increase the overall operational efficiency of our manufacturing facilities. Some of these efforts include the following:

- Removing and/or investing in new equipment, replacing processes, and exploring new technology to maximize operational efficiencies and minimize emissions.

- Replacing coal-fired boiler with electrical heater to eliminate discharge of emissions.

- Replacing fluorescent lamps with LEDs to decrease electrical usage.

- Changing old annealing furnace insulating layer to improve heat insulation effect and decrease electrical consumption by 40%.

- Replacing heaters and air conditioning units with newer energy-efficient units.

- Creating processes that maximize raw material yield, conserving energy and natural resources through prudent use and reuse, eliminating/minimizing waste at its source, and properly disposing of or effectively treating any waste that is not recycled.

- Updating coolant recycle machine to remove oil and sterilization by ozone to decrease the amount of bad coolant being disposed by 40%.

- Collecting and reusing wooden crates to ship products between manufacturing plants and end-users.

- Including packaging in the display of products to reduce the amount of packaging used.

- Processing and recycling broken tools from franchisees—at Snap-on’s cost—to effectively manage the product through its complete lifecycle.

- Designing, developing, and patenting technology to reduce environmental impacts in operations.

- Creating patented plating system, which has resulted in the reduction of hundreds to thousands of gallons of water used in plating locations.

- Designing and supplying solutions for use in alternative energy industries, such as wind turbines, and various products that can help improve automobile efficiency, such as engine diagnostics and precision tire alignment products.

- Developing facility-specific energy conservation plans and conducting energy-saving audits.